3 Tips to Unlock Working Capital with Smart Inventory Planning

Businesses across the US today face a number of external pressures. From an increase in inflation and labor and material shortages to swift changes in consumer buying behavior, these all add immense pressure on how effectively businesses can reduce supply risk and manage their inventory to meet demand.

But, this is not new news! We know that supply chains will face future disruptions, so it’s time to focus on the right inventory processes and best practices to enable you to make the best decisions for your supply chain by responding efficiently to changes and accelerating profitable growth.

So, how can businesses respond to changes and unlock working capital from their supply chain? It starts with inventory planning.

Here are three tips for improving your inventory planning.

1. Work with Enhanced Data

Managing hundreds of SKUs across multiple warehouses and working with various suppliers can be tricky. Throw in supplier delays or incorrect forecasting, and your inventory levels become harder to manage, leaving you with either excess stock or lost sales due to stocking out of crucial SKUs.

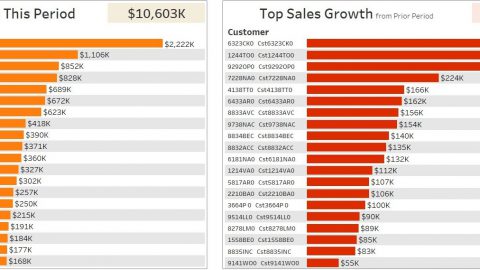

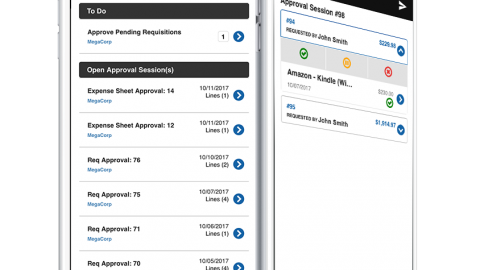

Data is vital to improving your inventory planning. Enhancing the data in your ERP with a supply chain planning tool gives you greater visibility into how your key inventory KPIs are performing.

- Enables your planning to be responsive to change. With predictive insights extracted from data in your ERP, you’ll be able to see “into the future” and adjust your planning quickly. Inventory is dynamic, so if you are still planning your inventory off static Excel spreadsheets, you won’t have real-time insights or automatic alerts if changes occur. If your supplier delivers earlier than expected or your forecast is incorrect, knowing this information in real-time lets you quickly review your open purchase orders or the amount of safety stock you need to carry for a particular SKU.

- Encourages team collaboration and quicker decision-making. Sharing data across sales, marketing, and finance departments breaks down siloed working habits. It also fosters sharing of ideas to improve customer service levels or providing updates on future sales campaigns where planners can ensure they have the right stock available. Most importantly, finance can report on potential cash flow expectations, where each department can work together to achieve the financial goals.

How can working with enhanced data unlock working capital?

- Enhanced data gives you predictive insights to make quick decisions. The closer you monitor your inventory KPIs the more you can improve your fill rate, which means meeting demand and happier customers.

- Real-time insights and a tool that automatically notifies you of potential stock-outs enable you to quickly pivot and potentially work with alternative suppliers to ensure you can meet demand and avoid a lost sale.

2. Classify Your Inventory

Focus 20% of your time and resources on the SKUs contributing to 80% of your sales. Not all SKUs have the same value, so classifying your inventory is smart planning and allows you to identify which SKUs need urgent attention.

Using the ABC analysis, you can classify each SKU into the following categories:

- A: highest value – your best-selling items

- B: medium value – the mid-range selling items

- C: least value – the remaining items

Once you know your high-performing SKUs, you can monitor lead times and check your target fill rates to ensure you have enough of these SKUs available in your warehouse to meet demand.

You can then further categorize your SKUs according to sales velocity.

- H = Items that have high sales

- M = Items that have medium sales

- L = Items that have low sales

With these two classifications in place, you can now order the right quantity needed for both the high-performing and low-performing SKUs.

Tayse Rugs integrated their Acumatica ERP with Netstock and successfully classified their inventory and reduced stock-outs.

“For me, the Netstock classification matrix is an impressive feature as it looks at your high-value and high-velocity items and plots them on a matrix that defines each item’s level of importance in your business. We could quickly see which were our slow-moving items and, by running promotions, could reduce those. We now have that “big picture” view and can action things like potential stock-outs before it becomes a problem.” – Sevimli, Business Development Manager at Tayse Rugs.

Read more about Tayse Rug’s story here.

How can classify inventory unlock working capital?

Firstly, classifying your stock will identify which SKUs are obsolete, these are items you will no longer stock or place orders for, and items that are non-stoked, these are items you only order when your customer requests the item. For the remaining obsolete stock items you may still have in stock, you can plan promotions to get rid of those items quickly so that they don’t continue to take up unnecessary space in your warehouse. The more unnecessary items you store in your warehouse, your holding costs increase.

Knowing which SKUs to focus on will help to reduce over-forecasting on the wrong items for which there is no demand. If you have low-performing excess stock, you can quickly work with your sales and marketing departments to run campaigns to free your business of those items and unlock working capital.

3. Monitor and measure suppliers’ performance.

Your suppliers are a critical link in your supply chain and where you probably spend a fair amount of time and resources. Working with reliable suppliers who deliver on time, in full, and offer MOQs that support your planning all form part of supplier best practices and how well you can meet demand. Supplier lead time is an external factor that is out of your control, so having the ability to measure and monitor supplier lead time automatically is another vital step to improving inventory planning.

Regarding your supplier network, it’s good to ask yourself:

- How well does your supply chain serve your customers?

- How can enhanced data enable efficient decision-making?

Key best practices working with suppliers:

- Review your supplier network to mitigate as much risk as possible.

- Consider alternative suppliers and have a well-trusted 2nd-tier supplier network in place.

- Increase the frequency of communication with your suppliers – the more you know what’s going on in their environment, the better prepared you can be.

- Share your purchasing forecast with your suppliers, so they can be prepared to support your future requirements.

How can supplier performance unlock working capital?

- Unreliable suppliers will hurt your bottom line. Having the ability to identify weak-performing suppliers, allows you to source alternative suppliers immediately.

- To measure lead time reliability, you can factor this information into your replenishment decisions, ensuring you order the right amount of items that will arrive at the right time.

- The more accurate the lead time reliability, the more accurate you can calculate the right amount of safety stock required for each SKU, enabling consistent customer service levels.

- Measuring supplier data will improve forecasting accuracy, where you can see how much money you will be spending in the next 12 -18 months and how that will impact your cash flow.

External events will continue to impact your supply chain and your ability to plan efficiently. Enhanced data will provide the visibility you need to be better prepared and adopt your planning where necessary. Classifying your inventory will identify where you need to focus your time and resources. Measuring how well your suppliers perform to increase your customer service levels.

About Netstock

Netstock is the leader in supply chain planning software, giving 2,200 global organizations predictive insights to maximize their inventory investment. Netstock integrates with leading global ERPs and leverages real-time data to provide prescriptive recommendations for the most important supply chain decisions you need to make today. For more information: www.netstock.com